Tempering batch furnaces

- Flexiblility

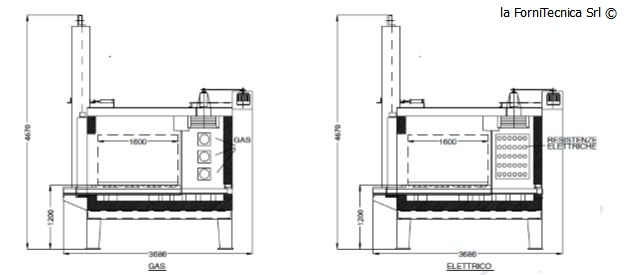

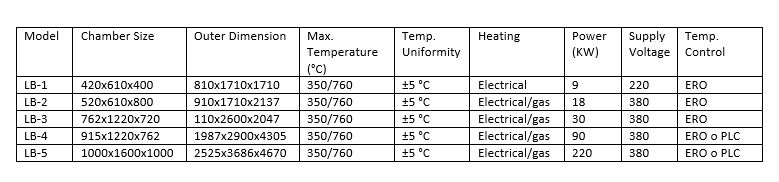

- Available in electric or gas version

- Powerful and uniform atmosphere circulation

- High efficiency

- Fast treatment

- Allows use of many different tray types

- Reliable

- Both heating and cooling system

General Purpouse:

- Annealing

- Drawing

- Heating

- Tempering

- Nitrogen Treatments

Lo-Batch furnaces can be either electrically or by gas and can operate up to 600 °C, they work by convection with the heating area placed behind the furnace.

During operation, all the circulating flow is forced to impinge on the electric or gas heating elements, while high throughput circulation fans insure uniformity of temperature.

The furnarce is designed for treatments in a range of 100 to 600 °C.

Thermal cycles are automatically managed by an electronic regulator.

When the door is completely opened, it is kept in its position by a security blocking system. At each door opening, both the heating system and the circulating fans are blocked.

A loading plane inside the furnace provides distribution of the pieces to be treated

The furnace is heated by a group of cromax resistors placed horizontally within the side walls, near the back of the furnace, according to the typical La ForniTecnica design for convection furnaces.

The Temperature is controlled through an ERO regulator ( or equivalent), the termal cycle is complitely automatic and the control panel is on the side of the furnace, it contains all the control devices for temperatura and power distribution, the SCR groups and the 24Vdc power supply for auxiliary circuits.

Download Info