Hardening Batch Furnaces with Integral Quench (Q) System

Main Features:

- Flexible operations

- Hardening can be performed in liquid or gas

- Single-block plant forn an easy installation

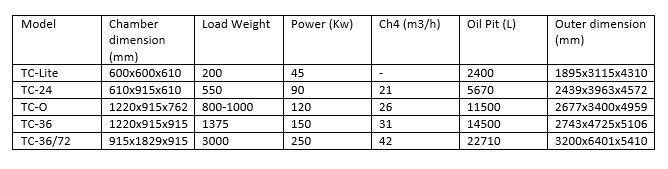

- Load weight from 200 Kg to 3000 Kg

- Fast temperature rise

- Safety features embedded

- Reliable operation

- Robust and easy-to-mantain

- Fast and acurate assistance

- Process quality report produced by a control system

- Self-diagnosis and maintenance advice embedded in the control system

- Carburizing

- Carbonitriding

- Soft Nitriding

- Moulds

- Hardening

- Normalizing

- Annealing

Batch furnaces with hardening pit, heated by gas radiant tubes, with a fan providing air circulation. Operating range of temperature from 760 °C to 970 °C. with +/- 5 °C temperature uniformity.

All plant operations are managed by our Holo-View supervising system, located in an external PC. This system is interfaced to a Siemens PLC, that control: load moving operations, temperatur regulation and gas distribution.

Carbon potential regulation is provided by our oxygen probe and our Holo-Carb system, interfaced to the Holo-View system through an Ethernet line.

A CO analyser provides a correcting signal to the oxygen probe.

Download Info